Iron Ore

What is iron ore?

Iron ores are rocks and minerals from which metallic iron can be extracted. There are four main types of iron ore deposit: massive hematite, which is the most commonly mined, magnetite, titan magnetite, and pisolitic ironstone. These ores vary in colour from dark grey, through to deep purple, rusty red and bright yellow. Iron is responsible for the red colour in many of our rocks and the deep red sands of the Indian deserts.

How is iron ore used?

98 per cent of all iron ore is converted into pig iron for steel making. It is then used in construction, transportation, energy infrastructure and even household appliances.

Construction

Buildings, bridges and other essential infrastructure around the world are built with steel that’s made from iron ore.

Household appliances

You’ll find steel in everyday household appliances like your ovens, washing machines, fridges and dishwashers.

Transport

Every mode of transportation relies on the steel that’s produced from iron ore. That includes planes, trains, ships, trucks and cars.

Energy infrastructure

From wind turbines to electricity poles, steel plays an essential role in providing the energy infrastructure that powers our world.

How is steel made ?

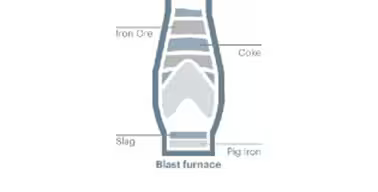

Mixing with coke

Iron ore is mixed with coke from super-heated metallurgical coal in a blast furnace.

Heating

Air that has been heated to around 1,200°C is injected into the furnace, converting the iron ore to molten pig iron and slag

Removing impurities

Once impurities are removed, alloying elements are added. The steel is then cast, cooled and rolled, ready for use.

Where is iron ore found?

Iron ore deposits have been located all over the world, with India, Australia, Brazil, the United States and Canada being the largest producing countries. We have interests in iron ore assets in India.

How is iron ore mined ?

From pit to port, our iron ore undergoes a series of processes before export.

- First, we explore the geology of the region to find the best iron ore prospects for our operations.

- Once the ideal site has been chosen, the ore is drilled and blasted.

- It is then transported to the primary crusher for processing.

- The crushed ore is sorted over screens and resized to different specifications, such as lump and fines products.

- Once the iron ore is processed, a stacker builds a stockpile in the stockyards.

- When ready for transportation, a reclaimer picks up the ore from the stockpiles and conveys it to train load out facilities.

- Trains transport the iron ore to ports.

- The iron ore is then loaded on to ships at our port facilities and exported to our customers around the world.

What is the future for iron ore ?

As the world continues to require steel for key construction and infrastructure projects, we expect demand for iron ore to continue into the future. Our challenge is to continue producing this vital commodity in a way that supports decarbonisation efforts, and reduces the greenhouse gas emissions footprint of our productions.